Overview

Cell therapy offers the potential to treat diseases by replacing or repairing damaged cells and tissues, including cancer, blood disorders, and neurological conditions, and even potentially cure diseases that currently have no other options.

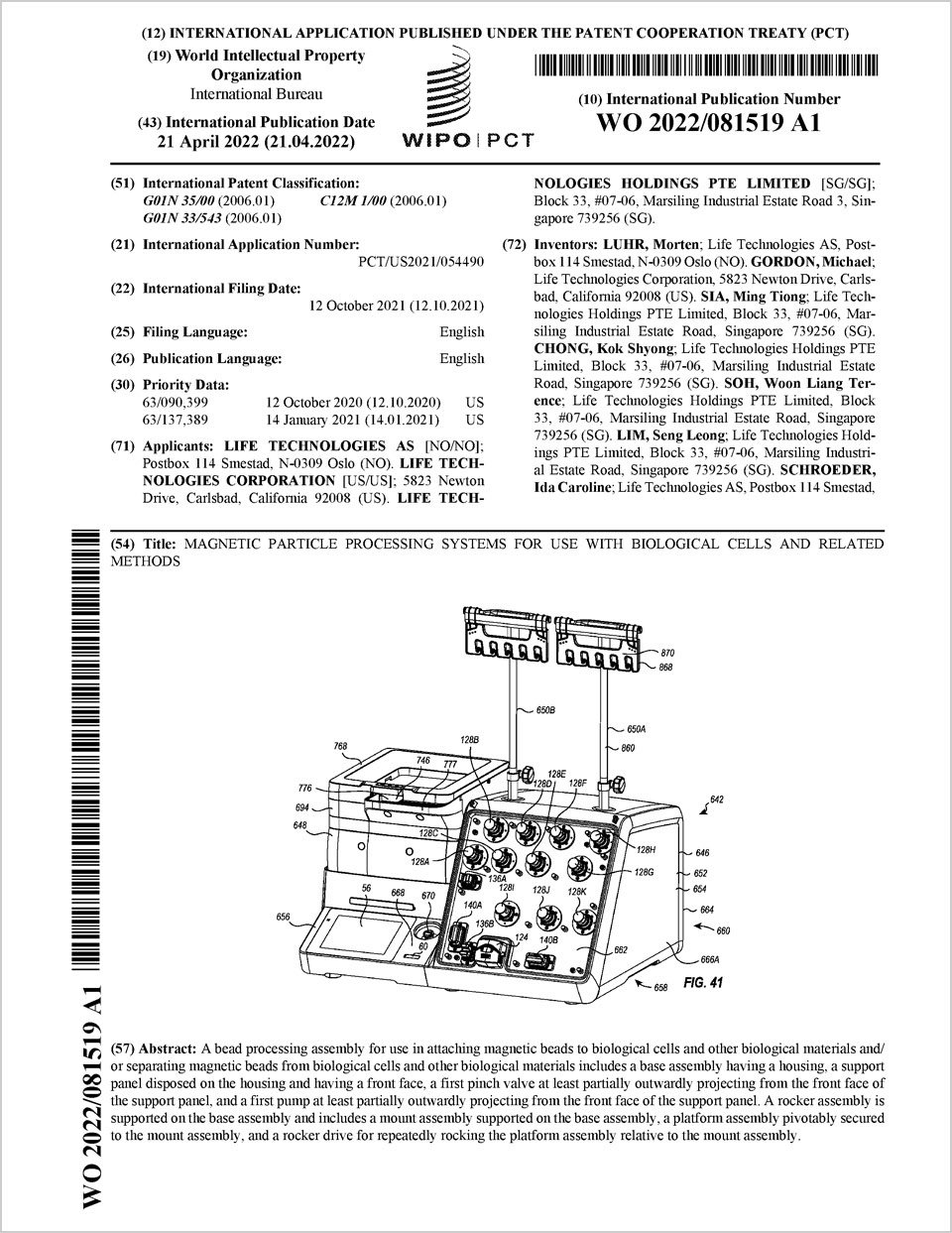

The Gibco DynaCellect™ instrument is critically important to this process. Specifically, it is a closed, automated system designed for rapid cell isolation and bead removal in cell therapy manufacturing - delivering high efficiency and purity while preserving cell viability. It's critical because it streamlines the manufacturing process enabling faster, more efficient production of high-quality cell therapies.

How it Works

First off, the system uses magnetic beads to capture and isolate target cells from a cell suspension. Once that is done, the DynaCellect system uses a closed, automated process to remove the magnetic beads, ensuring a high purity of the isolated cells. These healthy white blood cells are then set up for reprogramming - to attack a specific cancer, for example. Once this is done, the cells are then repopulated back into the patients blood, where it is transfused back to the body, to do the work.

Automation and Flexibility

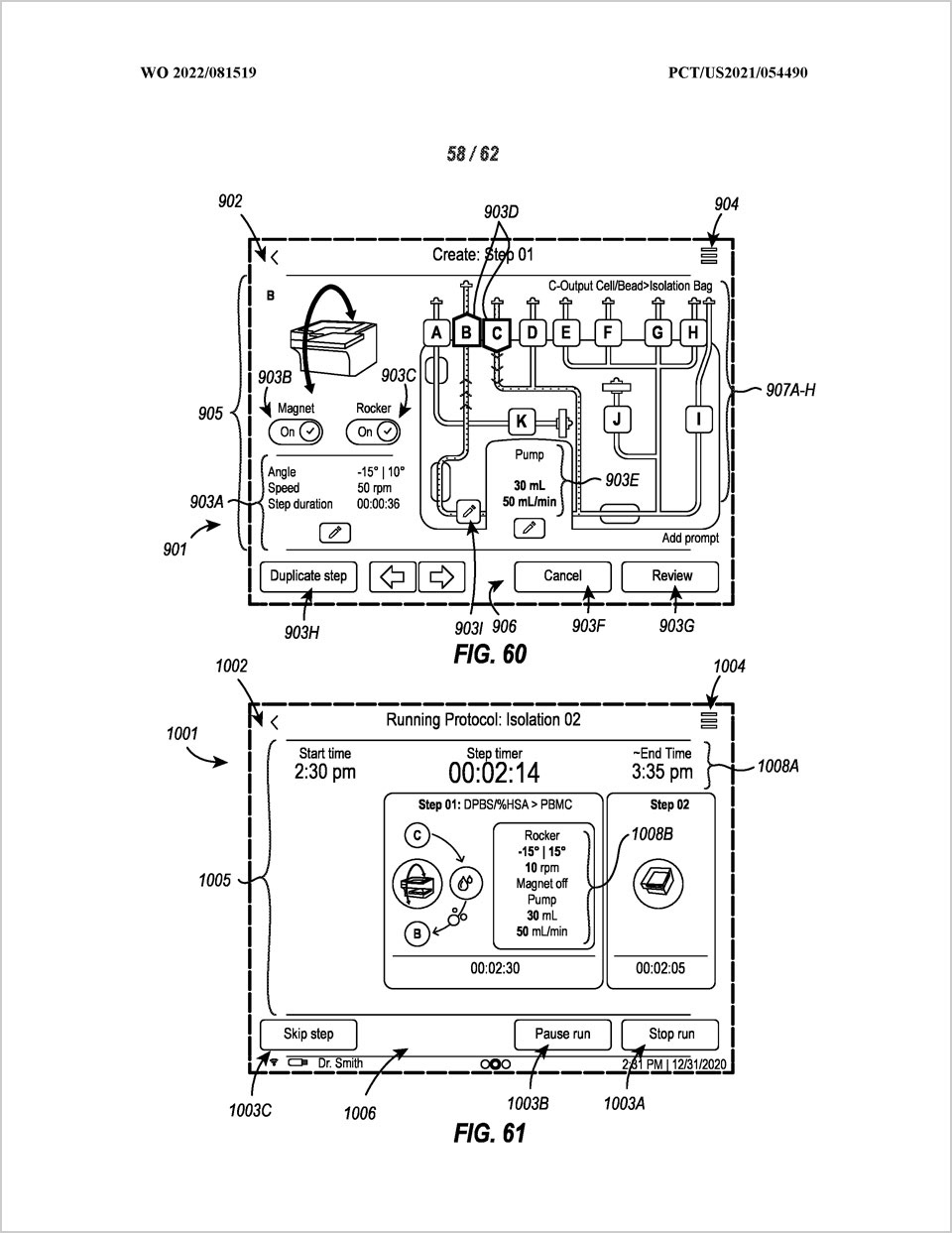

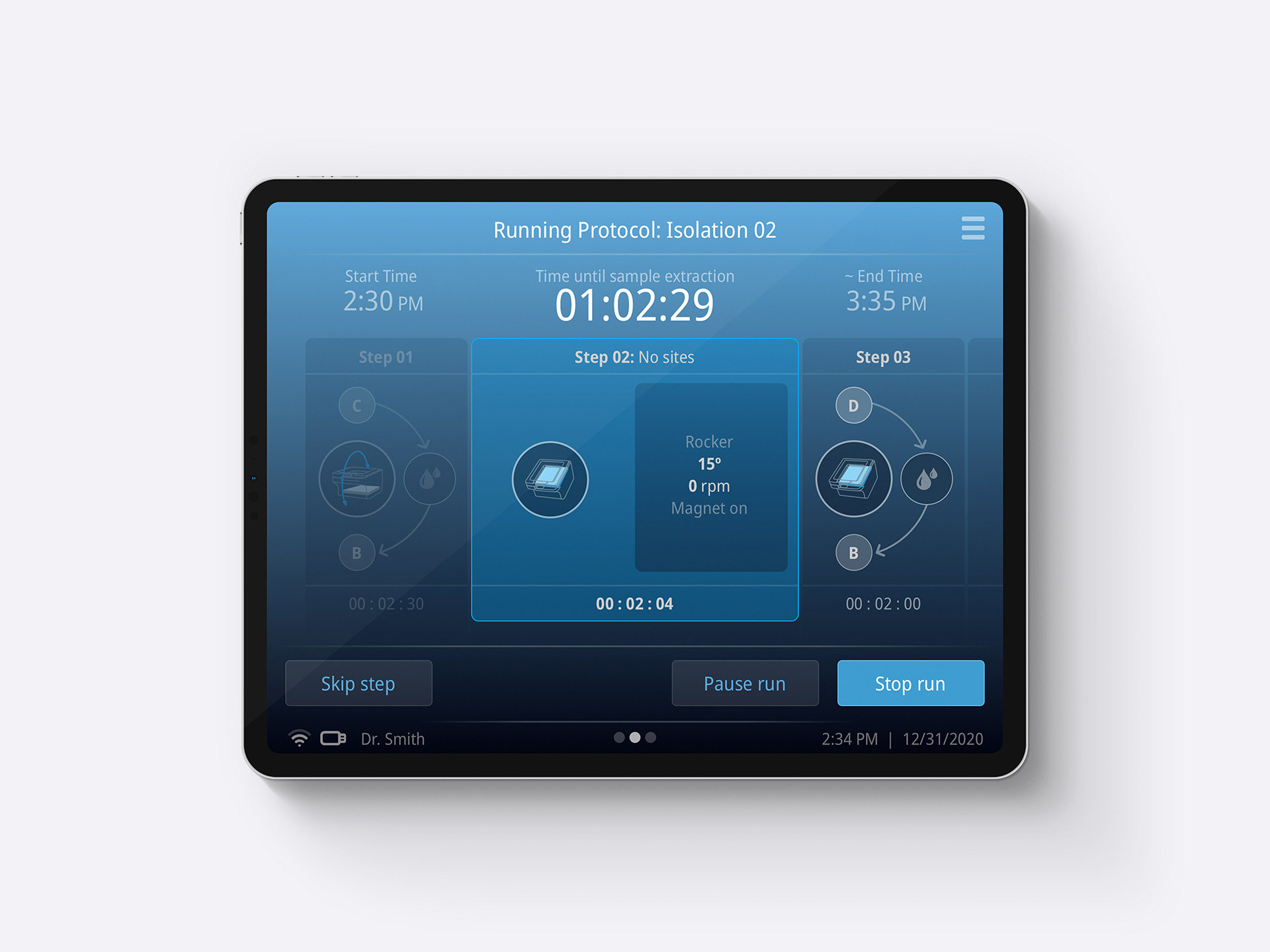

What made this instrument unique was the need for automation to reduce manual handling and errors, while also being flexible enough to support various cell therapy workflows. Scientists needed the ability to prototype custom “recipes” for different protocols. The setting up of these protocols needs to be easy, so gaining an understanding of the user needs was the first place to begin. What parameters make up a specific protocol? Once that's understood, I could then visualize a screen that gives them control of everything. In this case, they needed to control a "magnet", "rocker", and "tube sites" (which tubes push liquid where).

Entering parameters is what creates the "steps" that make up the recipe. Once those are figured out, it's all about how to easily control those parameters, using a touch screen.

From a UX perspective, I designed two visualizations that showcase what a step looks like:

1. A vertical list view displaying each step and its required parameters:

2. A horizontal visual flow for a more intuitive, at-a-glance representation

Usability testing revealed that users preferred the numbered list format for programming protocols. However, during the run, they benefited from the visual flow, which clearly indicated the previous, current, and upcoming steps in real time.

Keeping Engagement During a Run

For this instrument, it’s critical to keep scientists informed at all times. To support this, I designed multiple ways to visualize the run’s progress.

The homepage displays the remaining run time and the current step being executed. Swiping reveals a second screen with an illustration of the step-by-step process, allowing scientists to view the previous, current, and upcoming steps at a glance. Finally, a third screen shows the active tubes moving liquid through the system, as well as the rocker position and magnet.

Together, these views provide reassurance and clarity, ensuring everything is functioning as expected.

Award-Winning Results

The Gibco CTS DynaCellect Magnetic Separation System has become a successful and well-regarded instrument for cell therapy manufacturing. It has provided very positive outcomes and has won multiple industry awards. Specifically, it has

1. Improved Cell Purity by 95% while maintaining cell viability & enabling efficient target cell recovery.

2. Reduced Manufacturing Time (& costs) by 80%, due to the automated and closed system that streamlines the manufacturing process.

3. Enhanced Process Efficiency by enabling scientists to accelerate throughput, maximize consistency, and streamline the cell therapy manufacturing workflow.